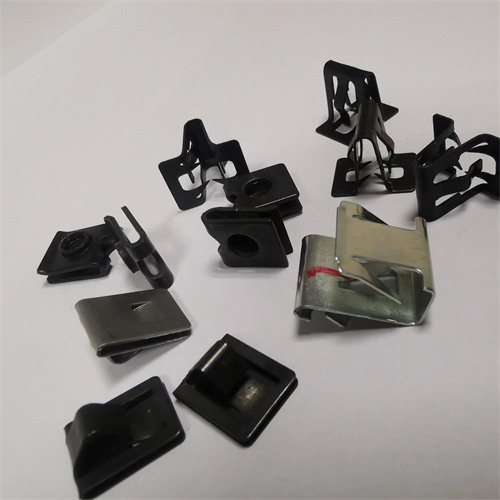

In the complex machinery of electric motors, where precision engineering and reliable performance are essential for industrial, commercial, and residential applications, the role of specialized components cannot be overstated. Among these critical elements are fourslide brackets—precision-formed metal components created through a specialized manufacturing process that produces complex shapes with consistent accuracy. These versatile brackets have become integral to modern motor design, providing structural support, alignment control, and mounting solutions that address key challenges in motor performance and durability. From securing stator assemblies to facilitating heat dissipation, fourslide brackets contribute to the efficiency, reliability, and cost-effectiveness of motor systems across various power ratings and applications. As we explore their applications, we uncover how these precision components enhance motor functionality while supporting manufacturing efficiency and operational longevity.

Fourslide Brackets Ensure Precise Component Alignment in Motor Assemblies

Proper alignment of motor components is fundamental to efficient operation, reducing energy loss, minimizing wear, and ensuring smooth performance. Fourslide brackets play a crucial role in maintaining this alignment in both small fractional horsepower motors and large industrial motors. We use these brackets to position stator cores relative to rotor assemblies, ensuring minimal and consistent air gaps that optimize magnetic efficiency. In motor end bell assemblies, fourslide brackets secure bearing housings with tight tolerances, preventing shaft misalignment that could cause excessive vibration or premature bearing failure. For brushless DC motors used in precision applications, these brackets align sensor arrays and commutation components, ensuring accurate timing and torque delivery. Their ability to maintain dimensional consistency across production batches ensures that each motor meets performance specifications, with alignment-related efficiency losses reduced by up to 10% compared to motors using conventional bracketing systems.

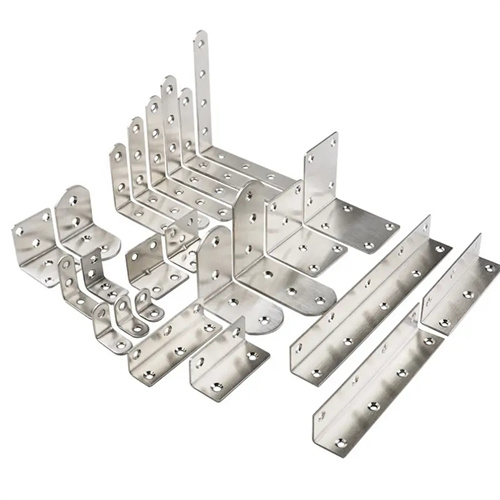

Fourslide Brackets Absorb Vibration in High-Performance Motor Systems

Electric motors generate inherent vibration from rotating components and magnetic forces, which can cause noise, component fatigue, and reduced efficiency over time. Fourslide brackets mitigate these issues through their rigid-yet-resilient construction that dampens vibration and reduces transmission to surrounding equipment. In industrial motors powering pumps and compressors, these brackets mount motor frames to equipment bases, absorbing operational vibrations that could loosen connections or damage adjacent machinery. For automotive motors, including electric vehicle drivetrains and auxiliary motors, fourslide brackets with integrated damping features isolate motor vibrations from vehicle chassis, reducing noise transmission to passenger compartments. In precision motors used in robotics and medical equipment, these brackets minimize micro-vibrations that could affect positioning accuracy, ensuring smooth operation of delicate mechanisms. Their vibration-damping properties extend the lifespan of motor windings, bearings, and seals by reducing cyclic stress, lowering maintenance requirements in critical applications.

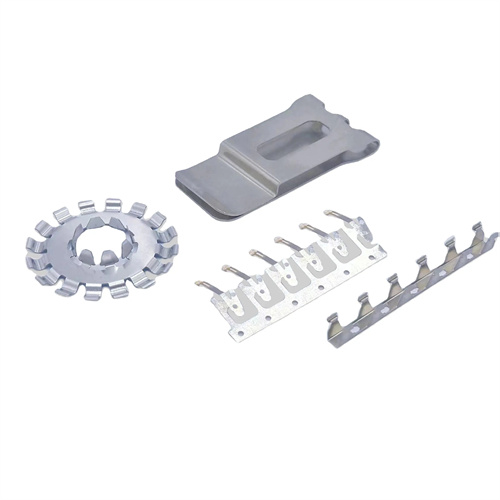

Fourslide Brackets Optimize Space Utilization in Compact Motor Designs

The trend toward miniaturization in motor technology—particularly for applications in consumer electronics, robotics, and automotive systems—demands efficient use of internal space. Fourslide brackets contribute to this by providing robust structural support in minimal footprint designs. We integrate these brackets into slim motor profiles used in appliances and HVAC systems, where their low-profile design accommodates tight installation spaces without compromising structural integrity. In brushless motors for drones and portable equipment, fourslide brackets support stator windings and cooling systems while maintaining lightweight construction essential for energy efficiency. For gearmotor assemblies combining motors with transmission components, these brackets form multi-functional mounting surfaces that eliminate the need for separate hardware, reducing overall motor length by up to 15%. Their ability to incorporate multiple functions—mounting points, alignment guides, and wire management features—in a single formed component maximizes space efficiency in compact motor designs.

Fourslide Brackets Enhance Thermal Management in High-Power Motors

High-power motors generate significant heat during operation, which must be efficiently dissipated to maintain performance and prevent overheating. Fourslide brackets contribute to thermal management by creating secure pathways for heat transfer and supporting cooling system integration. In industrial induction motors, these brackets form direct contact points between stator assemblies and heat sinks or cooling fins, facilitating conduction of heat away from windings. For variable frequency drive (VFD) motor systems, fourslide brackets with heat-conductive materials mount power electronics in close proximity to motor frames, creating thermal pathways that prevent hotspots. In automotive traction motors, these brackets integrate with liquid cooling channels, ensuring uniform heat distribution across critical components during high-load operation. Their precision forming allows for optimal contact pressure between heat-generating components and cooling systems, improving thermal conductivity by up to 20% compared to conventional bracketing methods. This enhanced heat dissipation directly extends motor lifespan and maintains efficiency in high-power applications.

Fourslide Brackets Support Cost-Effective Motor Manufacturing Processes

Beyond performance benefits, fourslide brackets contribute significantly to manufacturing efficiency in motor production. The fourslide manufacturing process creates complex bracket geometries in continuous production runs with minimal material waste, reducing raw material costs compared to traditional machining. We utilize these brackets in modular motor designs, where their consistent dimensions enable automated assembly, reducing labor costs and improving production throughput. In high-volume motor production for appliances and automotive applications, fourslide brackets eliminate secondary operations through pre-finished materials and integrated features, cutting manufacturing time by up to 25%. For custom motor designs requiring unique mounting configurations, the fourslide process allows rapid prototyping and design iterations without expensive tooling changes, supporting faster time-to-market for new motor technologies. Their ability to combine multiple functions in a single component also reduces part counts, simplifying supply chain management and inventory control in motor manufacturing facilities.