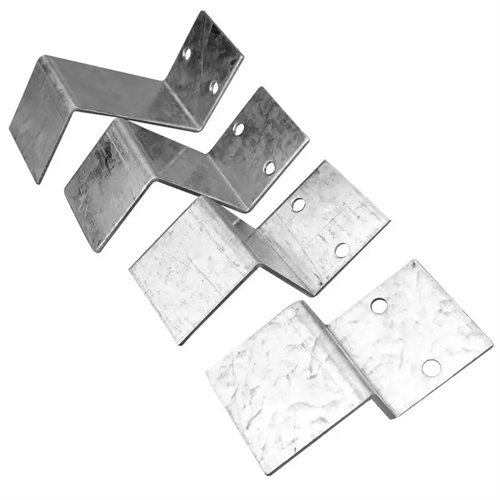

In the intricate network of heating, ventilation, and air conditioning (HVAC) systems, where reliability, efficiency, and safety are paramount, the role of precision mounting components often goes unnoticed. Among these essential elements are fourslide brackets—durable, precision-formed metal components that have become indispensable in modern HVAC installations. These versatile brackets provide secure mounting, vibration damping, and thermal management support across residential, commercial, and industrial heating and cooling systems. From securing ductwork in high-rise buildings to stabilizing refrigeration equipment in industrial facilities, fourslide brackets address key challenges in HVAC design and operation. As we explore their applications, we uncover how these robust components enhance system performance, extend equipment lifespan, and improve installation efficiency in heating and cooling infrastructure.

Fourslide Brackets Secure Ductwork and Piping in HVAC Systems

HVAC systems rely on properly positioned ductwork and piping to ensure efficient airflow and fluid distribution throughout buildings. Fourslide brackets provide the secure mounting necessary to maintain this critical alignment. We use these brackets to suspend rectangular and round ductwork from ceilings and structural framing, their precision-formed shapes distributing weight evenly to prevent sagging or misalignment. In commercial buildings, fourslide brackets secure large diameter refrigerant lines and hot water pipes, maintaining proper slope for drainage and preventing stress on joints that could cause leaks. For underground HVAC utilities and geothermal loops, these brackets anchor piping to trench walls or concrete slabs, protecting against shifting soil and external pressure. Their ability to accommodate varying sizes and installation orientations ensures consistent support across all components of an HVAC system, reducing energy loss from misaligned ducts and minimizing the risk of water damage from pipe failures.

Fourslide Brackets Dampen Vibration in HVAC Mechanical Equipment

HVAC systems generate significant vibration from fans, compressors, and pumps, which can cause noise pollution, component wear, and loosened connections over time. Fourslide brackets mitigate these issues through their rigid-yet-resilient construction that absorbs and isolates vibrational energy. In air handling units and rooftop HVAC packages, these brackets mount fan motors and blower assemblies to equipment housings, reducing noise transmission through ductwork and building structures. For chillers and cooling towers, fourslide brackets with vibration-damping properties secure compressor mounts to concrete pads, preventing vibration-related damage to piping connections and electrical components. In residential HVAC systems, these brackets isolate furnace blowers and condenser units from building frames, minimizing operational noise that could disturb occupants. Their ability to dissipate vibrational energy extends the lifespan of bearings, belts, and motor windings, reducing maintenance requirements and improving overall system reliability.

Fourslide Brackets Support Thermal Management in HVAC Equipment

Temperature fluctuations are inherent in HVAC operation, causing materials to expand and contract—a phenomenon that can stress rigidly mounted components. Fourslide brackets address this challenge by providing controlled flexibility that accommodates thermal movement while maintaining secure positioning. We use these brackets in high-temperature heating systems to mount hot water boilers and radiant heating pipes, allowing for expansion during heating cycles without creating destructive forces. In refrigeration systems, fourslide brackets secure evaporator coils and condenser units, accommodating cold-induced contraction while maintaining proper airflow around heat exchange surfaces. For rooftop HVAC units exposed to extreme outdoor temperatures, these brackets mount insulation panels and access doors, preventing gaps that could compromise thermal efficiency. Their ability to maintain secure connections through thermal cycles ensures consistent heat transfer and airflow, directly contributing to HVAC system efficiency and reducing energy consumption.

Fourslide Brackets Enhance Installation Efficiency in HVAC Projects

HVAC installation schedules demand efficient mounting solutions that reduce labor time and minimize disruption to building occupants. Fourslide brackets contribute to this efficiency through their standardized design and easy installation features. In new construction, these brackets enable rapid mounting of ductwork, pipes, and equipment, with pre-punched holes and snap-fit designs that eliminate the need for on-site fabrication. For retrofitting existing buildings with updated HVAC systems, fourslide brackets provide adaptable mounting solutions that work with irregular structural configurations, reducing modification needs to existing building elements. In modular HVAC installations, these brackets create uniform connection points that simplify system assembly, allowing crews to complete installations up to 25% faster than with traditional bracketing methods. Their consistent dimensions across production runs ensure reliable fitment, reducing installation errors and rework while maintaining compliance with building codes and industry standards.

Fourslide Brackets Optimize Space Utilization in Compact HVAC Designs

Modern buildings—particularly high-rises and urban structures—demand HVAC systems that maximize space efficiency without compromising performance. Fourslide brackets enable this by providing robust support in minimal footprint designs. We integrate these brackets into slim-profile ductwork systems used in apartment buildings and office spaces, where their low-profile design fits within limited ceiling plenums and wall cavities. In rooftop HVAC installations with space constraints, fourslide brackets create compact mounting systems for condensers and air handlers, allowing multiple units to be positioned efficiently. For under-floor air distribution systems, these brackets secure supply registers and branch ducts in tight spaces beneath raised floors, maintaining proper airflow without sacrificing usable floor height. Their ability to combine structural support with space-saving design allows HVAC engineers to maximize system performance within the physical constraints of modern building designs.