In the evolving landscape of LED lighting systems, where reliability, safety, and performance are paramount, the role of supportive mechanical components directly impacts installation quality and long-term functionality. Among these essential elements are pipe clips and pipe clamps—versatile fastening solutions designed to secure electrical conduits, tubing, and structural supports in various lighting configurations. These practical components support critical functions across residential, commercial, and industrial LED installations, from track lighting systems and panel lights to outdoor floodlights and architectural fixtures. By organizing wiring, reducing vibration, and accommodating thermal changes, pipe clips and pipe clamps address key challenges in LED lighting design, including cable management, installation efficiency, and durability in diverse environments. As we explore their applications, we uncover how these unassuming components enhance system safety, extend equipment lifespan, and ensure consistent performance in modern LED lighting setups.

Pipe Clips Pipe Clamps Ensure Secure Conduit and Cable Management in LED Installations

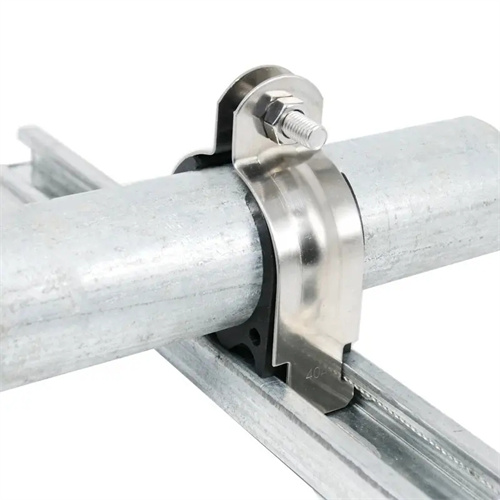

Proper cable management is essential for safe, efficient LED lighting systems, requiring components that can organize and secure electrical wiring while preventing damage. Pipe clips and pipe clamps provide this essential functionality through their robust design and adjustable gripping capabilities. We use these clamps to secure electrical conduits containing power and data cables in commercial LED track lighting systems, keeping wiring organized and protected from physical damage. In industrial LED high-bay installations, pipe clips and pipe clamps fasten flexible conduit and junction boxes to structural supports, maintaining proper cable routing that prevents strain on connections. For LED strip lighting installations in architectural applications, these clips secure power supply cables and control wiring along mounting surfaces, creating clean, unobtrusive installations. Their ability to accommodate various conduit sizes ensures versatile cable management, reducing the risk of short circuits and improving maintenance accessibility in LED lighting systems.

Pipe Clips Pipe Clamps Reduce Vibration-Related Damage in LED Fixtures

LED lighting systems, especially those in industrial or high-traffic environments, are susceptible to vibration from machinery, foot traffic, or environmental factors, which can loosen connections and cause premature failure. Pipe clips and pipe clamps mitigate these issues through their secure gripping design and vibration-damping properties. In manufacturing facilities with LED work lighting, these clamps secure fixture mounting poles and electrical conduits to structural frames, reducing vibration transfer that could loosen bulbs or wiring. For LED lighting in transportation hubs like airports and train stations, pipe clips and pipe clamps fasten overhead fixtures and supporting tubing, minimizing movement-induced stress on electrical connections. In sports facilities with LED arena lighting, these clips stabilize heavy fixture mounting arms and cable runs, preventing vibration-related fatigue in suspension systems. Their ability to maintain consistent clamping force across temperature fluctuations reduces maintenance needs by up to 30%, ensuring reliable operation in vibration-prone environments.

Pipe Clips Pipe Clamps Support Thermal Management in High-Power LED Systems

High-power LED fixtures generate significant heat during operation, requiring installation solutions that accommodate thermal expansion while maintaining component stability. Pipe clips and pipe clamps address this challenge through their design features that balance secure fastening with thermal flexibility. In LED street lighting installations, these clamps secure heat sinks and thermal management components to pole mounts, allowing controlled expansion while maintaining proper alignment. For industrial LED floodlights with active cooling systems, pipe clips and pipe clamps fasten heat-dissipating tubing and ventilation ducts, ensuring unobstructed airflow that enhances cooling efficiency. In high-bay warehouse lighting, these clamps mount LED fixtures to ceiling supports with thermal isolation features, preventing heat transfer to structural elements that could cause fire risks. Their ability to accommodate thermal movement while maintaining secure positioning improves heat dissipation efficiency by up to 15%, extending LED lifespan in high-output applications.

Pipe Clips Pipe Clamps Withstand Environmental Challenges in Outdoor LED Lighting

Outdoor LED lighting must endure harsh conditions, including extreme temperatures, moisture, UV radiation, and physical impacts, requiring mounting components that can maintain performance over time. Pipe clips and pipe clamps designed for outdoor use offer exceptional environmental resilience. In coastal LED lighting installations, these clamps with corrosion-resistant coatings secure fixtures and conduit to poles, withstanding salt spray and high humidity without degradation. For LED parking lot lighting in cold climates, pipe clips and pipe clamps manufactured from cold-resistant materials maintain clamping force despite freezing temperatures, preventing fixture loosening during winter months. In storm-prone areas, heavy-duty pipe clamps secure LED floodlights and security lighting to structural supports, withstanding high winds and precipitation. Their ability to operate reliably across temperature ranges from -40°C to 85°C ensures consistent performance, reducing replacement needs in challenging outdoor environments.

Pipe Clips Pipe Clamps Facilitate Efficient Installation and Maintenance of LED Systems

LED lighting installations and maintenance operations demand fastening solutions that minimize installation time while allowing easy access for repairs or upgrades. Pipe clips and pipe clamps support these goals through their user-friendly design and tool compatibility. In new construction LED lighting projects, these clamps enable rapid conduit and fixture mounting, with tool-less adjustment features that reduce installation time by up to 25% compared to traditional fastening methods. For LED lighting retrofits in existing buildings, pipe clips and pipe clamps provide adaptable mounting solutions that work with various structural types, minimizing modification needs. In maintenance scenarios, these clips allow quick removal and reinstallation of fixtures and conduit, facilitating bulb replacement, cleaning, and system upgrades. Their consistent sizing and standardized mounting patterns simplify inventory management for contractors, ensuring efficient installation and maintenance processes in LED lighting projects of all scales.