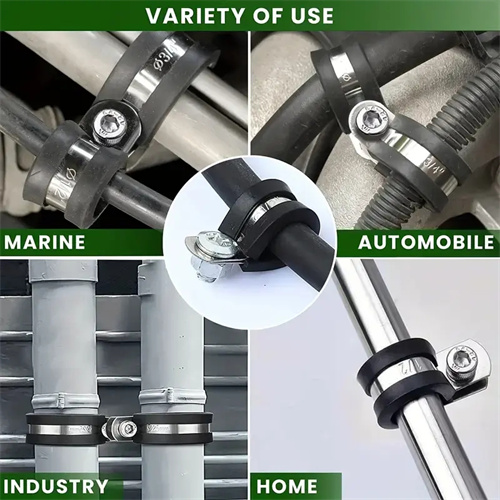

In the intricate network of automation equipment, where precision, reliability, and efficiency are paramount for uninterrupted production, the role of supportive fastening components directly impacts system performance and operational longevity. Among these essential elements are pipe clips and pipe clamps—versatile mechanical devices designed to secure cables, tubing, and small components in various automated systems. These practical components support critical functions across manufacturing lines, robotic cells, and industrial control systems, from conveyor belts and assembly robots to sensor arrays and hydraulic actuators. By organizing utilities, reducing vibration, and maintaining component alignment, pipe clips and pipe clamps address key challenges in automation design, including downtime prevention, precision maintenance, and durability in harsh industrial environments. As we explore their applications, we uncover how these unassuming components enhance system reliability, improve production efficiency, and ensure consistent performance in the demanding operation of automation equipment.

Pipe Clips Pipe Clamps Ensure Organized Cable Management in Automated Systems

Automation equipment relies on complex networks of power cables, data lines, and sensor wiring that require systematic organization to maintain signal integrity and prevent interference. Pipe clips and pipe clamps provide this essential functionality through their adjustable design and secure gripping capabilities. We use these clamps to fasten Ethernet cables and power cords in robotic workcells, keeping wiring organized and separated to prevent electromagnetic interference with sensitive control signals. In conveyor systems with automated guided vehicles (AGVs), pipe clips and pipe clamps secure sensor cables and communication lines along tracks and frames, maintaining consistent routing that minimizes connection failures. For industrial control panels and PLC installations, these clips organize wiring harnesses and terminal connections, simplifying troubleshooting and reducing downtime during maintenance. Their ability to accommodate various cable diameters and insulation types ensures versatile management, reducing the risk of system malfunctions in automated production lines.

Pipe Clips Pipe Clamps Stabilize Fluid and Pneumatic Lines in Automation Equipment

Many automated systems depend on hydraulic and pneumatic power for actuation, requiring secure fastening of fluid lines to maintain pressure integrity and precise movement control. Pipe clips and pipe clamps provide this essential functionality through their high-strength design and pressure-resistant properties. We use these clamps to secure hydraulic hoses in robotic arms and material handling equipment, preventing kinking and movement that could cause pressure drops or leaks. In packaging machinery with pneumatic actuators, pipe clips and pipe clamps fasten air lines to frame structures, maintaining consistent pressure delivery to cylinders and grippers. For automated assembly equipment with lubrication systems, these clips secure oil lines and distribution manifolds, ensuring reliable lubricant delivery to moving parts. Their ability to handle pressures up to 3,000 psi ensures safe operation, reducing the risk of fluid leaks and equipment damage in pressure-dependent automation systems.

Pipe Clips Pipe Clamps Reduce Vibration-Induced Wear in Moving Automation Components

Automation equipment generates significant vibration from motors, conveyors, and moving parts, which can loosen connections, fatigue components, and degrade performance over time. Pipe clips and pipe clamps mitigate these issues through their vibration-damping properties and secure mounting design. In high-speed packaging lines with rotating components, these clamps secure sensor brackets and camera mounts, reducing vibration that could affect inspection accuracy. For robotic welding cells with high-amplitude vibrations, pipe clips and pipe clamps fasten power cables and cooling lines to robot arms, preventing fatigue-induced failures in critical connections. In automated machining centers, these clips secure coolant lines and chip conveyor hoses, absorbing operational vibrations that could loosen fittings or disrupt fluid flow. Their ability to reduce vibration transfer by up to 40% extends component lifespan, lowering maintenance requirements in high-cycle automation applications.

Pipe Clips Pipe Clamps Withstand Harsh Conditions in Industrial Automation Environments

Automation equipment operates in diverse harsh environments, from dusty manufacturing floors and washdown areas to high-temperature processing zones, requiring components that maintain performance despite contamination and temperature extremes. Pipe clips and pipe clamps designed for industrial use offer exceptional environmental resilience. In food and beverage automation with frequent washdowns, these clamps with stainless steel construction and corrosion-resistant coatings secure tubing and cables, withstanding chemical sanitizers and moisture. For automotive manufacturing lines with welding sparks and debris, pipe clips and pipe clamps resist heat damage and particulate buildup, maintaining secure fastening in dirty conditions. In pharmaceutical packaging automation with strict cleanliness standards, these clips with smooth surfaces prevent bacterial accumulation while securing utility lines. Their ability to operate reliably across temperatures from -20°C to 120°C ensures consistent performance, reducing replacement needs in challenging automation environments.

Pipe Clips Pipe Clamps Facilitate Flexible Automation System Integration and Maintenance

Modern automation requires modular designs that support quick reconfiguration and easy maintenance, demanding fastening solutions that balance security with accessibility. Pipe clips and pipe clamps support these needs through their tool-friendly design and adjustable features. In modular production cells with frequent retooling, these clamps enable rapid installation and removal of cables and tubing, reducing changeover time by up to 25%. For predictive maintenance programs, pipe clips and pipe clamps with quick-release mechanisms allow easy access to sensors, actuators, and connection points, simplifying inspection and replacement. In automated test equipment with frequent calibration needs, these clips provide adjustable positioning for measurement probes and sensor arrays, ensuring precise alignment during setup. Their standardized sizing and compatibility with industry mounting systems streamline inventory management, supporting efficient integration and maintenance in dynamic automation environments.