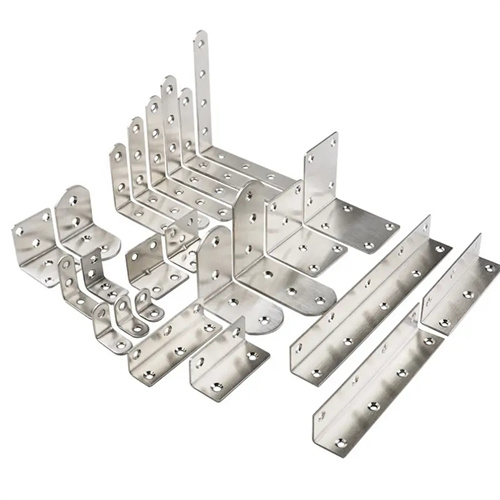

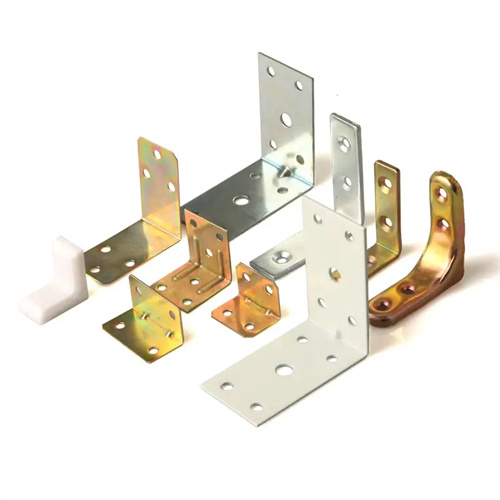

Initial Cost Analysis: Fourslide Brackets vs. Traditional Alternatives

We’ve found that when analyzing initial costs, Fourslide Brackets often present a favorable comparison to traditional brackets, especially for complex designs. Traditional brackets frequently require multiple manufacturing steps—stamping, bending, and welding—each adding to labor and tooling expenses. Fourslide Brackets, by contrast, are produced in a single pass using multi-slide machines, reducing labor time and minimizing tooling needs. While the upfront cost of fourslide machinery is higher, this is offset by lower per-unit costs for medium to large production runs. For example, a project requiring 10,000 brackets with three bends saw a 15% lower initial cost with Fourslide Brackets compared to traditional stamped and welded alternatives. Even for smaller runs, the reduced need for secondary operations makes Fourslide Brackets a cost-competitive choice, avoiding the added expenses of assembling multiple parts.

Long-Term Savings: Durability Reducing Replacement Costs of Fourslide Brackets

The durability of Fourslide Brackets translates to significant long-term savings by reducing replacement and maintenance costs. Traditional brackets, often made from multiple joined parts, are prone to failure at welds or connection points, requiring frequent replacements. Fourslide Brackets, being a single piece with no seams, withstand wear and stress better—we’ve observed them lasting 2–3 times longer in high-vibration industrial settings. This longevity cuts down on the labor and material costs of swapping out worn brackets. In a manufacturing plant using conveyor systems, switching to Fourslide Brackets reduced annual replacement costs by 40% over five years. Their resistance to corrosion and deformation also means fewer unplanned shutdowns for repairs, further boosting long-term cost-effectiveness.

Reduced Assembly Time: Labor Savings with Fourslide Brackets

Fourslide Brackets streamline assembly processes, leading to substantial labor savings that enhance project cost-effectiveness. Their precise design and consistent dimensions ensure they fit seamlessly with mating components, eliminating the need for time-consuming adjustments or modifications. Traditional brackets often require filing, bending, or re-drilling to achieve a proper fit, adding minutes to each assembly step. In a project assembling 500 units, we found that using Fourslide Brackets reduced assembly time per unit by 12 minutes—a total savings of 100 labor hours. This efficiency is particularly valuable in high-volume production, where even small time reductions per unit multiply into significant cost savings. Additionally, the one-piece design of Fourslide Brackets eliminates the need to fasten multiple parts together, further cutting assembly steps.

Material Efficiency: Minimizing Waste with Fourslide Brackets

Material efficiency is a key contributor to the cost-effectiveness of Fourslide Brackets, as their manufacturing process generates minimal waste. Traditional stamping methods often produce excess scrap metal from trimming and shaping, with material waste rates as high as 30% for complex parts. Fourslide Brackets, however, are formed from continuous metal strips with precise cutting, reducing waste to less than 5% in most cases. This not only lowers material costs but also reduces disposal fees for scrap. For a project using 1,000 pounds of stainless steel, switching to Fourslide Brackets saved 250 pounds of material—equating to a 20% reduction in material expenses. The ability to use thinner gauges of material without sacrificing strength, thanks to their optimized design, further enhances material efficiency and cost savings.

Customization Without Excessive Costs: Fourslide Brackets for Unique Projects

Fourslide Brackets offer cost-effective customization for unique projects, avoiding the exorbitant expenses often associated with custom traditional brackets. Traditional custom brackets require expensive, specialized dies for stamping, which can cost thousands of dollars and take weeks to produce—prohibitive for small runs or prototype projects. Fourslide Brackets, by contrast, use adjustable tooling that can be modified quickly and cheaply to accommodate design changes. This allows for prototypes and small batches to be produced at a fraction of the cost. For a custom medical device bracket, we found that Fourslide Brackets reduced tooling costs by 70% compared to traditional custom stamping. The ability to integrate multiple features (tabs, holes, bends) into a single bracket also eliminates the need for additional custom parts, further lowering project costs.

Scalability Benefits: Cost-Effectiveness of Fourslide Brackets Across Project Sizes

Fourslide Brackets maintain cost-effectiveness across project sizes, from small prototypes to large-scale production, thanks to their scalable manufacturing process. For small projects (100–500 units), their low tooling costs and quick setup times avoid the high per-unit expenses of traditional methods. For medium to large projects (1,000+ units), the efficiency of the fourslide machine—capable of producing hundreds of brackets per hour—drives down per-unit costs. We’ve seen this scalability in action: a project starting with 200 prototype brackets saw per-unit costs drop by 40% when scaled up to 10,000 units, without compromising quality. This ability to scale without significant cost increases makes Fourslide Brackets a versatile choice, ensuring cost-effectiveness throughout a project’s lifecycle, from development to full production.