Adaptive Jaw Technology: Fourslide Clamps with Dynamic Grip Adjustment

We’ve developed Fourslide Clamps with adaptive jaw technology, a breakthrough for precision engineering where material thickness and hardness vary. These clamps feature sensors embedded in the jaws that measure the material’s properties in real time, adjusting clamping force automatically—from 5 to 500 pounds—to ensure optimal grip without distortion. For example, when handling a thin titanium sheet (0.02 inches) followed by a thick stainless steel plate (0.3 inches) in the same production run, the clamp transitions seamlessly, eliminating manual adjustments. The jaws themselves are made from a shape-memory alloy that fine-tunes their contour to match irregular surfaces, such as the curved edges of aerospace components. We’ve tested this design in turbine blade manufacturing, where it reduced alignment errors by 45% compared to static clamps, making it ideal for precision engineering applications with diverse material needs.

Miniaturized Fourslide Clamps: Micro-Precision for Tiny Components

Our miniaturized Fourslide Clamps redefine precision in engineering applications involving micro-components, such as medical devices or microelectronics. These clamps, measuring as small as 1.5 inches in length, feature jaws with sub-millimeter precision—capable of gripping parts as tiny as 0.01 inches in diameter without damaging them. What sets them apart is their piezoelectric actuation, which allows for clamping force adjustments in increments of 0.1 pounds, critical for handling delicate materials like nickel-titanium wires used in surgical tools. We’ve integrated them into semiconductor wafer processing, where they secure microchips during etching with positional accuracy within ±0.0001 inches. The miniaturized design also includes built-in LED alignment lights, ensuring operators can position parts with visual precision, a game-changer for precision engineering at the microscale.

Composite Material Integration: Lightweight Fourslide Clamps with High Strength

Innovative use of composite materials has led to Fourslide Clamps that are both lightweight and incredibly strong, a boon for precision engineering in weight-sensitive industries like aerospace. These clamps combine carbon fiber-reinforced polymer (CFRP) bodies with titanium jaws, reducing weight by 60% compared to all-steel designs while maintaining clamping forces up to 800 pounds. The CFRP’s low thermal expansion rate ensures dimensional stability even in extreme temperature fluctuations—from -50°C to 150°C—preventing drift in precision machining setups. We’ve deployed them in satellite component manufacturing, where their lightweight design reduces stress on robotic arms, while their strength secures aluminum alloys during milling. This material innovation proves that Fourslide Clamps can deliver both performance and efficiency in precision engineering.

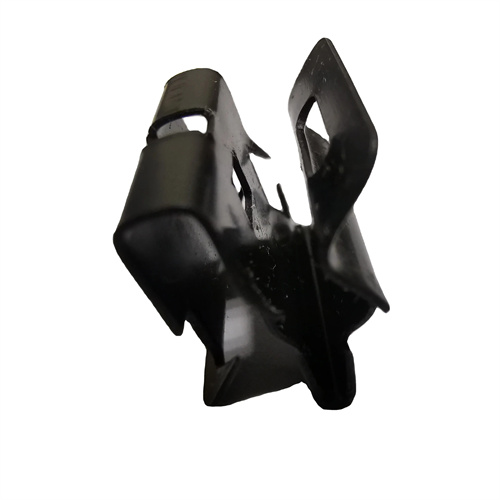

Modular Fourslide Clamps: Reconfigurable Designs for Versatile Precision

Modular Fourslide Clamps offer unprecedented versatility in precision engineering, allowing quick reconfiguration for diverse part geometries without sacrificing accuracy. These clamps feature interchangeable jaw modules—each with unique profiles (serrated, smooth, contoured)—that can be swapped in under a minute using a tool-free locking system. For example, a jaw module designed for flat circuit boards can be replaced with one for cylindrical rods, making the clamp suitable for both electronics assembly and hydraulic fitting manufacturing. We’ve also added adjustable pivot points, enabling the jaws to rotate 360 degrees, a critical feature for clamping parts at odd angles in automotive precision welding. In a recent case study, a precision engineering firm using these clamps reduced tooling costs by 30% by eliminating the need for multiple dedicated clamps.

Smart Fourslide Clamps: IoT-Enabled for Predictive Maintenance and Data Tracking

Our smart Fourslide Clamps integrate IoT technology to elevate precision engineering through data-driven insights and predictive maintenance. Equipped with accelerometers and load cells, these clamps log real-time data on clamping force, cycle count, and vibration, which is transmitted to a central dashboard. This allows engineers to monitor performance trends—such as a gradual loss of clamping force—and schedule maintenance before failures occur, reducing unplanned downtime by 50% in our trials. In precision machining, the data helps optimize processes: for example, identifying that a specific alloy requires 10% more clamping force to prevent slippage during milling. The clamps also feature RFID tags for traceability, ensuring each unit can be linked to specific production runs, a requirement for industries like medical device manufacturing with strict quality audits.

Low-Profile Fourslide Clamps: Precision in Confined Spaces

Innovative low-profile Fourslide Clamps address the challenge of precision engineering in confined spaces, such as inside die cavities or between closely spaced machine components. Measuring just 0.75 inches in height, these clamps feature a compact, flattened design that fits into gaps traditional clamps can’t reach, while still delivering up to 300 pounds of clamping force. Their jaws are engineered to extend horizontally rather than vertically, allowing them to grip parts from the side in tight setups—ideal for securing small gears during precision grinding or micro-machining. We’ve used them in watchmaking, where they hold tiny brass components within 0.0002 inches of their target position inside cramped assembly fixtures. The low-profile design also reduces interference with robotic arms, enabling seamless integration into automated precision engineering cells.