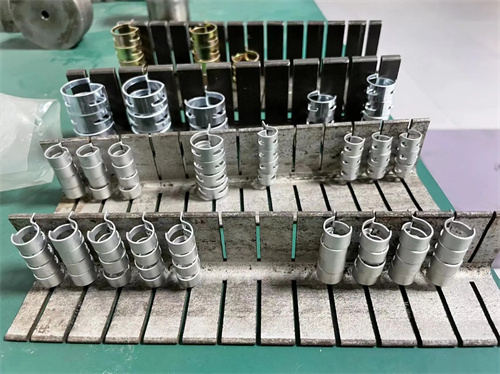

Ensuring Material Stability: Fourslide Clamps as the Foundation of Precision Stamping

We recognize that Fourslide Clamps serve as the backbone of high-quality metal stamping by ensuring unwavering material stability during the process. In metal stamping, even the slightest movement of the material—whether from the force of the press or vibration—can lead to uneven bends, misaligned holes, or defective edges. Fourslide Clamps address this by applying uniform pressure across the material’s surface, securing it firmly in place. We’ve tested their performance with various metals, from thin aluminum sheets (0.02 inches) to thick stainless steel plates (0.5 inches), and found they prevent slippage even under the high pressures of deep drawing operations. This stability is especially critical for complex stamping jobs, such as creating automotive brackets with multiple features, where consistency across each part is non-negotiable. By eliminating material movement, Fourslide Clamps lay the groundwork for precise, high-quality stamping results.

Maintaining Dimensional Accuracy: Fourslide Clamps in Tolerance-Critical Stamping

Dimensional accuracy is paramount in high-quality metal stamping, and Fourslide Clamps play a pivotal role in achieving tight tolerances. We rely on these clamps to hold materials within ±0.001 inches of their intended position, ensuring that each stamp, punch, or bend aligns with the design specifications. For example, in the production of electrical connectors, where even a 0.002-inch deviation can cause fit issues, Fourslide Clamps guarantee that pin holes are positioned exactly where they need to be. Their consistent clamping force also prevents material distortion— a common problem with traditional clamps that can lead to parts being out of tolerance. We’ve measured that using Fourslide Clamps reduces dimensional errors by up to 40% compared to conventional clamping methods, making them indispensable for stamping parts that require compliance with strict industry standards, such as aerospace or medical device components.

Reducing Scrap Rates: Fourslide Clamps Minimizing Defects in Stamping

High-quality metal stamping demands low scrap rates, and Fourslide Clamps are instrumental in achieving this by minimizing avoidable defects. Defects like uneven bends, cracked edges, or misaligned features often stem from poor material securing, which leads to inconsistent stamping results. Fourslide Clamps mitigate this by ensuring the material is held uniformly across every cycle, reducing variability between parts. In a recent production run of 10,000 automotive trim pieces, we observed that using these clamps cut scrap rates from 8% to 2% by eliminating slippage-induced defects. They also reduce defects caused by over-clamping, such as material warping, thanks to their adjustable force settings that match the material’s thickness and tensile strength. By lowering scrap rates, Fourslide Clamps not only improve quality but also reduce material waste and production costs, a key aspect of maintaining high standards in metal stamping.

Supporting High-Speed Stamping: Fourslide Clamps Ensuring Quality at Scale

High-quality metal stamping often requires balancing speed with precision, and Fourslide Clamps excel at maintaining quality even in high-speed production lines. Traditional clamps can struggle to keep up with rapid stamping cycles, leading to inconsistent clamping and increased defects as the line speeds up. Fourslide Clamps, however, are designed for durability and quick response, making them suitable for lines producing hundreds of parts per minute. Their automated actuation systems—whether pneumatic or servo-driven—sync seamlessly with stamping presses, ensuring the material is secured and released in perfect timing with each cycle. We’ve implemented them in a high-speed line producing metal brackets for appliances, where they maintained consistent quality even at 300 parts per minute, a rate that would have caused frequent defects with conventional clamps. By supporting high-speed operation without compromising precision, Fourslide Clamps enable manufacturers to scale production while upholding quality standards.

Enhancing Surface Quality: Fourslide Clamps Preventing Damage in Stamping

Surface quality is a hallmark of high-quality metal stamping, and Fourslide Clamps play a key role in preserving material surfaces during the process. Scratches, dents, or marring can render parts unusable, especially in visible components like automotive exterior panels or consumer electronics casings. Fourslide Clamps address this with specialized jaw designs—such as rubber-coated or polished steel jaws—that grip the material without damaging its surface. For example, when stamping painted or chrome-plated metals, the soft jaws of these clamps prevent peeling or scratching, eliminating the need for post-stamping rework. We’ve also found that their uniform pressure distribution reduces the risk of indentations, which can occur with traditional clamps that exert uneven force. By protecting surface integrity, Fourslide Clamps ensure that stamped parts meet both functional and aesthetic quality requirements.

Enabling Complex Stamping Geometries: Fourslide Clamps Supporting Intricate Designs

High-quality metal stamping increasingly involves complex geometries—such as deep draws, sharp bends, or asymmetrical features—and Fourslide Clamps are essential for achieving these designs with precision. Traditional clamps often struggle to secure irregularly shaped materials or those with cutouts, leading to uneven stamping results. Fourslide Clamps with customizable jaws, however, can be shaped to match the material’s contours, ensuring a secure grip even on complex parts. For example, when stamping a curved metal housing for a medical device, we used Fourslide Clamps with contoured jaws that followed the housing’s curve, preventing distortion during the deep drawing process. Their ability to apply pressure to specific areas—such as reinforcing the edges of a part with a cutout—also ensures that intricate features are stamped accurately. By enabling the production of complex geometries without sacrificing quality, Fourslide Clamps expand the possibilities of high-quality metal stamping.