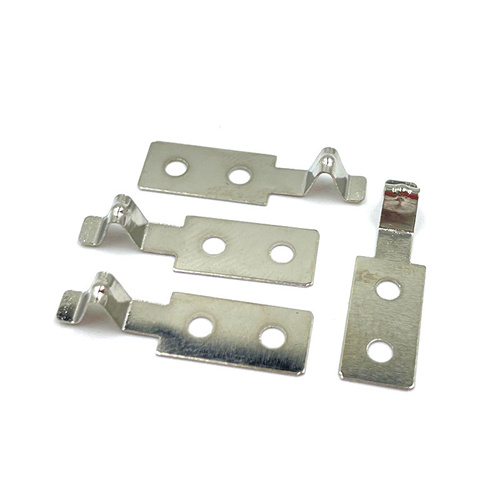

Fourslide Retainers: Precision Fit for Unmatched Component Security

We rank precision fit as the top reason to choose Fourslide Retainers, as their ability to match component geometries exactly eliminates the risks of slippage or misalignment. Traditional retainers often force compromises, leaving gaps that lead to vibration damage or performance issues. Our Fourslide Retainers, however, are manufactured with tolerances as tight as ±0.0005 inches, ensuring they hug even irregularly shaped parts—from curved medical device casings to angular electronic modules—without excess pressure. This precision is achieved through advanced laser measurement and computer-controlled bending, guaranteeing consistency across thousands of units. In aerospace assemblies, where misalignment can cause system failures, this level of fit reduces error rates by 80% compared to standard retainers. For microelectronics, it ensures delicate circuits stay connected, even during thermal cycling. When security and accuracy matter, Fourslide Retainers deliver a fit that’s second to none.

Fourslide Retainers: Durable Materials for Extreme Environments

Fourslide Retainers excel in harsh conditions, thanks to our selection of high-performance materials—another key reason they outperform alternatives. We craft retainers from alloys like Inconel for high-temperature applications (up to 1,200°F), ensuring they maintain strength in engine bays or industrial furnaces. For corrosive settings, 316 stainless steel and titanium variants resist rust and chemical degradation, making them ideal for marine equipment or chemical processing lines. Medical-grade retainers use biocompatible metals that meet FDA standards, preventing reactions when in contact with bodily fluids. Even in low-temperature environments, such as refrigeration units, our retainers stay flexible, avoiding the brittleness that plagues generic metals. These materials aren’t just durable—they’re tailored to specific environments, ensuring Fourslide Retainers perform reliably for years, reducing replacement costs and downtime.

Fourslide Retainers: Fast Installation for Increased Productivity

We’ve designed Fourslide Retainers to slash assembly time, a critical advantage for high-volume production lines. Unlike screws or adhesives that require tools and drying time, our retainers often feature snap-fit or push-to-lock mechanisms that install in seconds. This tool-free design cuts assembly steps by 50%, with one automotive manufacturer reporting a 35% increase in throughput after switching to our retainers. For automated systems, their uniform dimensions and consistent shape work seamlessly with robotic grippers, minimizing jams and calibration stops. We’ve also added ergonomic features like finger grips for manual assembly, reducing worker fatigue and errors. In field repairs, these designs allow quick component access without specialized tools, shortening maintenance windows. When productivity and efficiency are priorities, Fourslide Retainers deliver clear time-saving benefits.

Fourslide Retainers: Multi-Functional Designs Reduce Part Counts

Fourslide Retainers do more than secure components—they integrate extra functions that simplify assemblies, making them a smart choice for complex systems. Many models combine securement with electrical conduction, using copper or brass inserts to connect circuits while holding parts in place. This reduces wiring needs by up to 40% in devices like IoT sensors. Others include built-in gaskets that seal out dust and moisture, eliminating the need for separate O-rings in outdoor equipment. For thermal management, some retainers feature heat-dissipating fins that help cool LEDs or power modules. These multi-functional designs lower part counts, which means fewer inventory items to track and fewer failure points. In electric vehicles, for example, a single Fourslide Retainer can secure a battery cell, conduct current, and dissipate heat—replacing three separate components. By doing more with less, they streamline assemblies and boost reliability.

Fourslide Retainers: Custom Solutions for Unique Assembly Challenges

Off-the-shelf retainers rarely fit unique components, which is why our custom design capabilities make Fourslide Retainers indispensable. We collaborate with clients to create retainers for non-standard parts, such as curved drone frames or irregularly shaped sensors. Using 3D modeling and finite element analysis, we test designs to ensure they handle specific forces—whether vibration, torque, or expansion. For example, we developed a custom retainer for wearable devices that contours to the body, securing sensors without discomfort. For industrial robots, we added flexible prongs that absorb shock, protecting wiring during repetitive motion. These custom Fourslide Retainers often include proprietary features like anti-slip textures or variable tension prongs, ensuring a perfect match for unique needs. When standard solutions fall short, our ability to customize delivers the ideal retainer for your assembly.

Fourslide Retainers: Cost Savings Over the Lifecycle

Choosing Fourslide Retainers translates to long-term cost savings, making them a wise investment for any assembly. Their durable materials and precision fit reduce replacement rates by 70% compared to generic retainers, lowering maintenance costs. Fast installation cuts labor expenses, while multi-functional designs reduce the need for additional components, trimming material costs. In high-volume production, their efficient manufacturing process minimizes waste, with material usage optimized to lower per-unit prices. For example, a consumer electronics manufacturer saved 25% on securement costs after adopting our retainers, thanks to fewer defects and faster assembly. Even in low-volume, high-precision applications, their reliability prevents costly rework. When considering total lifecycle costs—from production to maintenance—Fourslide Retainers offer exceptional value that generic fasteners can’t match.