Fourslide Retainers: Accelerating Production Cycles with Rapid Manufacturing

We’ve witnessed how Fourslide Retainers revolutionize manufacturing timelines by slashing production cycles compared to traditional retainers. Our advanced fourslide machinery produces these retainers in continuous runs, with the ability to manufacture up to 500 units per minute—far outpacing the slower, batch-based processes of stamping or machining. This speed is game-changing for high-volume industries like automotive and consumer electronics, where meeting tight deadlines is critical. We’ve also optimized setup times: reconfiguring our machines for custom retainer designs takes hours, not days, allowing for quick transitions between production runs. For example, a client producing home appliances reduced their retainer production lead time by 60% after switching to our Fourslide Retainers, enabling them to respond faster to market demand. By minimizing production delays, these retainers act as a catalyst for overall manufacturing efficiency, ensuring that downstream assembly lines never wait for critical components.

Fourslide Retainers: Reducing Material Waste for Sustainable Savings

We’re proud that Fourslide Retainers drive sustainability in manufacturing by significantly cutting material waste, a key factor in both cost efficiency and environmental responsibility. The fourslide manufacturing process uses coiled metal strips precision-cut to the exact width needed, generating up to 70% less scrap than traditional stamping methods that carve retainers from large metal sheets. This efficiency translates to direct cost savings: a client in the aerospace sector reduced raw material expenses by 25% annually by adopting our retainers. Additionally, the minimal scrap produced is highly recyclable, aligning with circular economy goals and reducing disposal costs. We also engineer retainers to use thinner gauge metals without sacrificing strength, further lowering material usage. For manufacturers aiming to reduce their environmental footprint while boosting profitability, Fourslide Retainers offer a win-win solution that transforms waste into savings.

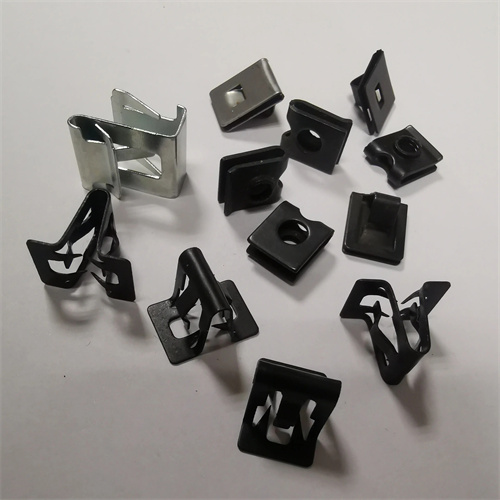

Fourslide Retainers: Streamlining Assembly with Tool-Free Installation

We’ve designed Fourslide Retainers to simplify assembly processes, a transformation that reduces labor costs and speeds up production lines. Unlike traditional fasteners that require tools, adhesives, or complex tightening steps, our retainers feature intuitive snap-fit or push-to-lock mechanisms that install in seconds. This tool-free design eliminates the need for specialized training, reducing onboarding time for new workers and minimizing human error. In automotive assembly plants, we’ve seen clients cut component installation time by 40% after switching to Fourslide Retainers, with one manufacturer increasing daily output by 1,200 units. For manual assembly teams, ergonomic features like finger grips reduce fatigue, maintaining productivity throughout shifts. By turning a once time-consuming step into a quick, straightforward task, these retainers redefine efficiency on the factory floor.

Fourslide Retainers: Enhancing Automation Compatibility in Modern Lines

We recognize that automation is the future of manufacturing, and Fourslide Retainers are engineered to seamlessly integrate with robotic systems, maximizing line efficiency. Their consistent dimensions, uniform weight, and predictable geometry make them easy for robotic grippers to handle, reducing jams and misplacements that disrupt automated workflows. Unlike irregularly shaped traditional retainers that require frequent calibration, our Fourslide Retainers feed smoothly into pick-and-place machines, maintaining steady production rates. We’ve also added alignment features like chamfered edges that guide robots to position retainers with pinpoint accuracy, reducing rework. A client in electronics manufacturing reported a 30% drop in automation downtime after adopting our retainers, as robots could process them with minimal errors. By acting as a bridge between human and machine workflows, Fourslide Retainers ensure that automated lines operate at peak efficiency.

Fourslide Retainers: Minimizing Rework with Consistent Quality

We stand behind the consistent quality of Fourslide Retainers, which drastically reduces rework and rejects—two major drains on manufacturing efficiency. Our production process includes real-time inspections with laser measurement tools and computerized quality checks, ensuring every retainer meets tolerances of ±0.001 inches. This uniformity means fewer fitment issues during assembly, unlike traditional retainers that often vary slightly in size, causing delays. In medical device manufacturing, where precision is critical, a client saw rework rates plummet by 75% after switching to our Fourslide Retainers, as each unit performed exactly as expected. We also provide detailed quality reports for every batch, allowing manufacturers to trace performance and quickly address any anomalies. By eliminating the need to inspect, repair, or replace faulty retainers, these components free up valuable time and resources for other production tasks.

Fourslide Retainers: Enabling Lean Manufacturing Principles

We’ve designed Fourslide Retainers to support lean manufacturing practices, helping businesses eliminate waste and optimize resource usage across processes. Their multi-functional designs reduce part counts—for example, a single retainer can secure a component while conducting electricity, eliminating the need for separate fasteners and wires. This simplification streamlines inventory management, as fewer SKUs mean less storage space, reduced ordering complexity, and lower carrying costs. Our flexible production model also supports just-in-time (JIT) manufacturing, with short lead times that allow clients to order only what they need, avoiding excess stock. A furniture manufacturer using our retainers reduced inventory holding costs by 35% by adopting JIT delivery, while also cutting waste from obsolete parts. By aligning with lean principles of simplicity, efficiency, and waste reduction, Fourslide Retainers become a cornerstone of streamlined, cost-effective manufacturing.