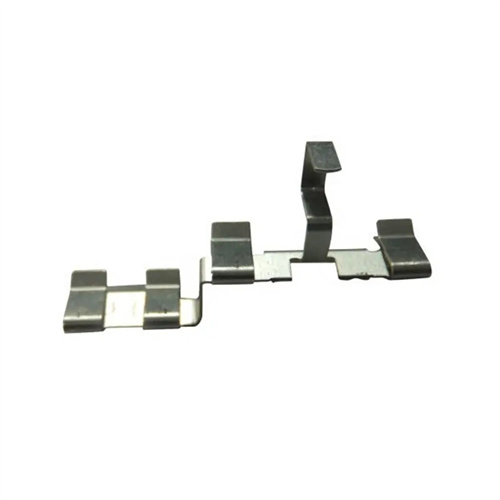

Fourslide Retainers

Production process of Fourslide Retainers

We utilize the advantages of the four slider process to accurately perform a series of operations such as stamping, bending, and forming on metal materials through the coordinated motion of four sliders on a single device. This process can complete multiple complex procedures in one molding cycle, greatly improving production efficiency while ensuring high precision and consistency of the product. For example, for Fourslide Retainers with complex shapes, multiple bending angles, and special structures, the four slide process can accurately process them according to design requirements without the need for tedious multi-step operations and manual adjustments, effectively reducing human errors.

Compared with traditional metal processing techniques, our four slider process has significant advantages in terms of molds. The mold used is relatively simple and the manufacturing cost is low, especially suitable for the production of small batches and customized products. Because in small batch custom production, traditional processes require the production of complex and expensive molds, while our four slide process can achieve the same product shape through simple molds, greatly saving costs. Moreover, mold replacement is convenient and can quickly respond to production needs of different product models and specifications, enhancing production flexibility.

Throughout the entire production process, we have established a strict quality control system. From the procurement of raw materials, strict inspections are carried out, and chemical composition analysis and physical performance testing are conducted on each batch of metal materials to ensure that they meet our high standards. In the production process, professional operators will monitor the operation status of equipment and the processing accuracy of products in real time. Once any subtle deviations or problems are found, they will be adjusted and corrected immediately. After the finished product is completed, a comprehensive visual inspection, dimensional measurement, and performance testing must be conducted on each Fourslide Retainers. Only products that fully meet or exceed customer requirements can enter the market.

Fourslide Retainers Material Selection

We offer a variety of high-quality metal materials to manufacture Fourslide Retainers to meet the specific needs of different customers. Common materials include spring steel and stainless steel. Spring steel has high elasticity and excellent fatigue resistance, which can withstand repeated stress without deformation or damage. It is very suitable for applications that require long-term maintenance of elasticity and fastening force, such as as as fixing and connecting components in some mechanical devices. Stainless steel is known for its excellent corrosion resistance and oxidation resistance, and is suitable for corrosive environments such as humidity, acidity, and alkalinity. For example, in outdoor equipment, food processing equipment, and some medical equipment with high hygiene requirements, the use of stainless steel Fourslide Retainers can ensure the service life and safety of the product.

In addition to conventional materials, we can also choose some special non-ferrous metal alloys or composite materials according to customers’ special requirements. For example, in the aerospace field, in order to reduce the weight of aircraft while ensuring structural strength, we can use lightweight and high-strength materials such as aluminum alloy or titanium alloy to manufacture Fourslide Retainers. For some electronic devices with special electromagnetic performance requirements, we can also choose alloy materials with corresponding characteristics to meet the special needs of the equipment in electromagnetic shielding, magnetic conductivity, and other aspects.

Fourslide Retainers Product Features

Fourslide Retainers have the characteristic of high precision. Our production equipment and processes can control the dimensional errors of products within a very small range, typically achieving precision of ± 0.005 inches or even higher. This enables it to achieve precise installation and connection when used in conjunction with other components, ensuring the stability and reliability of the entire system. For example, in electronic devices, high-precision Fourslide Retainers can accurately fix electronic components, avoiding problems such as poor contact or signal interference caused by dimensional deviations.

Our Fourslide Retainers are capable of achieving complex shape designs. The four slider process endows us with the ability to manufacture various unique shapes and structures, whether it is designs with irregular holes, special bending angles, or complex surface textures, we can easily achieve them. This complex shape manufacturing capability provides customers with greater flexibility in product design, which can meet the special needs of different industries and application scenarios. For example, in the design of automotive interior parts, we can produce Fourslide Retainers with complex shapes that match the interior styles of different car models. They not only serve as fixing and decorative elements, but also enhance the overall aesthetics of the interior.

The good surface quality of the product is also a major advantage of our Fourslide Retainers. Its surface is smooth and flat, without defects such as burrs or cracks. This not only makes the product more aesthetically pleasing, but also reduces the possibility of injury to other components or operators during use. At the same time, good surface quality is beneficial for subsequent surface treatment processes such as electroplating, spraying, anodizing, etc., which can make the coating adhere better, thereby improving the corrosion resistance, wear resistance, and decorative properties of the product.

Fourslide Retainers Applications

In the field of electronic devices, our Fourslide Retainers are widely used in the production of various electronic products, such as smartphones, tablets, laptops, etc. They can be used to fix various electronic components such as circuit boards, chips, batteries, etc., ensuring the stability of these components inside the device, preventing them from loosening or shifting due to vibration, collision, etc., thus ensuring the normal operation of electronic products. In addition, in some high-end audio devices, Fourslide Retainers can also be used to secure precise audio components, reduce the impact of vibration on sound quality, and improve the quality of audio playback.

The automotive industry is also an important application area for Fourslide Retainers. In the engine compartment of a car, they can be used to secure various pipelines, wiring harnesses, and small components to prevent them from shaking or shifting during engine operation, ensuring the normal working environment of the engine. In car interiors, Fourslide Retainers can be used to secure components such as seat adjustment mechanisms and door interior panels, improving the assembly quality and stability of the interior and providing passengers with a more comfortable and safe riding experience. In addition, in the chassis of the car, Fourslide Retainers can also be used to connect and secure some suspension system components, enhancing the overall integrity and reliability of the chassis.

In the aerospace industry, the quality and performance requirements for components are extremely demanding, and our Fourslide Retainers have an indispensable position in this field due to their high precision, high strength, and lightweight characteristics. For example, in the structural components of an aircraft, Fourslide Retainers can be used to connect and secure small components such as wings and fuselage, to withstand various stresses and vibrations during flight. In aviation engines, they can be used to fix some precision components inside the engine, ensuring stable operation of the engine under extreme working conditions of high temperature, high pressure, and high speed.

In addition to the aforementioned industries, our Fourslide Retainers also have extensive applications in many other fields. In furniture manufacturing, they can be used to connect the frames and panels of furniture, enhance the structural strength of furniture, and extend the service life of furniture. In the field of medical devices, Fourslide Retainers can be used to manufacture some fixtures and fixing devices in medical equipment, such as clamping parts for surgical instruments, sample fixing devices in medical testing equipment, etc., providing guarantees for the accuracy and safety of medical operations. In industrial automation equipment, Fourslide Retainers can be used to fix and connect various transmission components, sensors, etc., ensuring stable operation and precise control of the equipment.