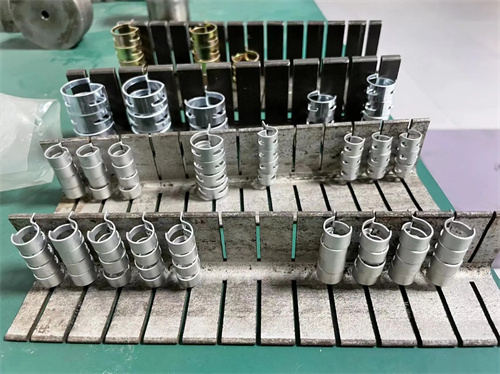

In the demanding landscape of industrial equipment, where reliability, durability, and efficiency directly impact productivity and safety, the role of specialized fastening components is paramount. Among these essential elements are fourslide clamps—precision-engineered metal components that have become integral to industrial machinery design and operation. These versatile clamps provide secure fastening, vibration damping, and alignment control across a wide range of industrial equipment, from manufacturing machinery and conveyor systems to heavy-duty processing units and automated production lines. From securing critical components in high-stress environments to facilitating efficient maintenance, fourslide clamps address key challenges in industrial settings, including operational durability, environmental resilience, and performance consistency. As we explore their applications, we uncover how these robust components enhance equipment reliability, extend service life, and support the rigorous demands of modern industrial operations.

Fourslide Clamps Ensure Secure Component Attachment in Heavy-Duty Machinery

Industrial machinery operates under extreme loads, repetitive motions, and constant stress, requiring fastening solutions that can maintain secure component attachment under these demanding conditions. Fourslide clamps provide the reliable securing necessary for critical parts in heavy-duty equipment. We use these clamps to secure conveyor belt guides, drive rollers, and tensioning systems in material handling equipment, ensuring consistent alignment that prevents jams and ensures smooth operation. In manufacturing presses and stamping machines, fourslide clamps mount tooling dies and workpiece fixtures, maintaining precise positioning that directly impacts product quality and dimensional accuracy. For industrial pumps and compressors, these clamps attach motor mounts, impellers, and housing components, preventing movement that could cause seal failure or efficiency loss. Their ability to maintain consistent clamping force across temperature fluctuations and vibration ensures reliable performance, reducing unplanned downtime in industrial production environments.

Fourslide Clamps Dampen Vibration in Industrial Machinery Operation

Industrial equipment generates significant vibration from motors, rotating components, and mechanical processes, which can cause premature wear, noise pollution, and operational inaccuracies over time. Fourslide clamps mitigate these issues through their vibration-damping properties that absorb and dissipate mechanical energy. In manufacturing facilities with CNC machining centers and robotic systems, these clamps mount control panels, sensor arrays, and feedback devices, reducing vibration transmission that could affect precision measurements or control signals. For power transmission equipment like gearboxes and drive shafts, fourslide clamps with damping features secure bearing housings and coupling assemblies, minimizing vibration-induced stress that could cause premature failure. In heavy machinery used in construction and mining, these clamps attach hydraulic components and control systems to equipment frames, absorbing operational vibrations that could loosen connections or damage sensitive electronics. Their ability to reduce vibration amplitude by up to 40% extends component lifespan and improves operator comfort in industrial workplaces.

Fourslide Clamps Enhance Thermal Management in Industrial Systems

Many industrial processes generate substantial heat that can degrade equipment performance, shorten component life, and create safety hazards if not properly managed. Fourslide clamps contribute to effective thermal management by optimizing heat transfer in industrial systems. In metalworking equipment like welding machines and furnaces, these clamps secure heat shields, cooling jackets, and thermal sensors, maintaining safe operating temperatures and preventing heat-related damage. For industrial ovens and drying systems, fourslide clamps mount heating elements and temperature control devices, ensuring uniform heat distribution that improves process efficiency. In power distribution cabinets and motor control centers, these clamps attach heat sinks and ventilation components to enclosures, preventing overheating of electrical components during high-load operation. Their precision design allows controlled clamping pressure that optimizes thermal conductivity without damaging heat-sensitive parts, improving overall system efficiency in temperature-critical industrial applications.

Fourslide Clamps Withstand Harsh Conditions in Industrial Environments

Industrial equipment operates in some of the harshest environments—from factories with chemical exposure to outdoor installations with extreme weather—requiring components that can endure these conditions without degradation. Fourslide clamps designed for industrial use provide exceptional environmental resilience. In food and beverage processing facilities, these clamps with corrosion-resistant finishes and sanitary designs secure conveyor systems and processing equipment, withstanding frequent washdowns and chemical sanitization. For oil and gas production equipment, fourslide clamps with rugged coatings attach sensors, valves, and pipeline components, resisting corrosion from hydrocarbons and environmental exposure. In mining and construction machinery, these clamps secure electrical systems and hydraulic components, withstanding dust, moisture, and temperature extremes. Their ability to maintain structural integrity across wide operating ranges (-40°C to 150°C) and resist chemical degradation ensures reliable performance in the toughest industrial environments.

Fourslide Clamps Facilitate Efficient Maintenance in Industrial Settings

Minimizing maintenance time and simplifying repair processes are critical for maximizing productivity in industrial operations. Fourslide clamps support these goals through design features that streamline equipment service and reconfiguration. In modular manufacturing systems and flexible production lines, these clamps enable quick changeover of tooling and workholding fixtures, reducing setup time between production runs by up to 35%. For industrial robots and automated equipment, fourslide clamps with tool-free release mechanisms allow easy access to motors, gears, and end-effectors, simplifying routine maintenance and component replacement. In process control systems and instrumentation, these clamps provide secure yet removable mounting for sensors and measurement devices, facilitating calibration and upgrades without extensive downtime. Their consistent dimensional accuracy across production runs ensures reliable interchangeability, reducing inventory costs and simplifying maintenance procedures in industrial facilities.