In the vast infrastructure of the power industry, where electricity travels from generation plants to homes and industries, reliability and safety are paramount. Behind the scenes of this complex network lies an essential component often taken for granted: cable clips and wire clamps. These small yet robust devices play a critical role in securing, organizing, and protecting the countless wires and cables that form the backbone of electrical systems. From power distribution stations to transmission lines and substation equipment, they ensure that electrical connections remain stable, organized, and protected against various hazards. Through our experience working across power generation, transmission, and distribution sectors, we’ve come to recognize that these unassuming tools are vital for maintaining the integrity and efficiency of electrical networks, directly impacting the reliability of power supply to communities and industries alike.

Cable Clips Wire Clamps Enhance Electrical Safety in Power Distribution

Safety is the cornerstone of power industry operations, and cable clips and wire clamps are frontline defenders in preventing electrical accidents. We use these devices to secure high-voltage cables in distribution panels, ensuring they remain firmly positioned and insulated from adjacent components. In switchgear installations, where multiple cables converge, insulated clamps create physical barriers between live conductors, eliminating the risk of short circuits caused by accidental contact. For overhead power lines, we deploy heavy-duty cable clips that anchor service drops to utility poles, preventing sagging wires that could pose electrocution risks to workers or the public. In underground cable vaults, corrosion-resistant clamps secure cables away from moisture and soil contaminants, reducing the chance of insulation breakdown that could lead to ground faults. Every clamp placement is strategically calculated to maintain safe distances between conductors, adhering to strict industry standards that protect both equipment and personnel.

Cable Clips Wire Clamps Maintain Order in Complex Electrical Panels

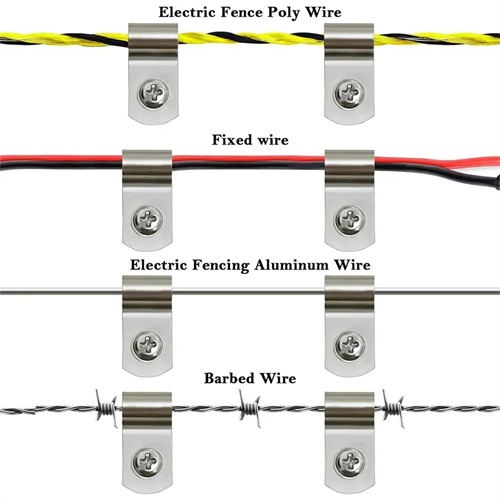

Electrical panels and control cabinets in power facilities house intricate networks of wires, from power cables to communication lines and sensor connections. We rely on cable clips and wire clamps to bring order to this complexity, grouping wires by function and routing them along designated pathways. Color-coded clips help us categorize cables—red for high-voltage power, blue for control signals, and green for grounding wires—making it easy for technicians to identify circuits during inspections or repairs. In smart grid installations with advanced monitoring systems, these clamps organize data cables alongside power lines without interference, ensuring that communication between meters, sensors, and control systems remains uninterrupted. By preventing cable tangling and maintaining consistent spacing, we also improve airflow within enclosures, helping to dissipate heat generated by electrical components and extending their operational life.

Cable Clips Wire Clamps Reduce Downtime by Preventing Cable Damage

Unplanned downtime in the power industry is costly, both in terms of repair expenses and lost productivity. Cable clips and wire clamps play a key role in minimizing such disruptions by protecting cables from damage. In industrial power plants, where machinery vibrations are constant, we use vibration-dampening clamps to secure cables, preventing abrasion from contact with metal surfaces or other cables. For mobile equipment like generator sets, shock-absorbing clips protect wiring harnesses from the jolts of transportation and operation, reducing the risk of loose connections or broken conductors. In coastal power facilities, stainless steel clamps resist saltwater corrosion, ensuring that cables remain secure even in harsh marine environments. Our data shows that properly clamped cables experience 50% fewer failures due to mechanical stress, significantly reducing maintenance costs and unplanned outages.

Cable Clips Wire Clamps Support Durability in Extreme Environmental Conditions

Power systems operate in some of the harshest environments on earth, from freezing utility poles in northern climates to desert substations with extreme temperature fluctuations. We select cable clips and wire clamps specifically engineered to withstand these conditions. In cold regions, we use UV-resistant, cold-flexible clamps that remain pliable in sub-zero temperatures, preventing cracking that could expose cables to moisture and ice. For power lines in tropical areas, heat-resistant clips made from silicone or fiberglass composites withstand prolonged exposure to direct sunlight, maintaining their gripping strength even at temperatures exceeding 60°C. In flood-prone areas, waterproof clamps with rubber gaskets seal cable entry points in junction boxes, preventing water intrusion that could cause electrical failures during storms. These specialized clamps ensure that electrical infrastructure remains operational regardless of environmental challenges.

Cable Clips Wire Clamps Facilitate Efficient Maintenance and Upgrades

The power industry is constantly evolving, with regular maintenance and system upgrades essential to meet growing energy demands. Cable clips and wire clamps simplify these processes by providing organized, accessible wiring systems. Detachable clips with quick-release mechanisms allow us to temporarily reposition cables during equipment servicing, eliminating the need to disconnect entire harnesses and reducing the risk of incorrect reconnections. In substation upgrades, modular clamp systems enable us to add new cables without disturbing existing connections, minimizing downtime during expansions. For troubleshooting, labeled clamps guide technicians directly to specific circuits, reducing diagnostic time and allowing faster repairs. This efficiency not only lowers maintenance costs but also ensures that power systems can be upgraded or repaired with minimal disruption to service, keeping electricity flowing reliably to homes and businesses.