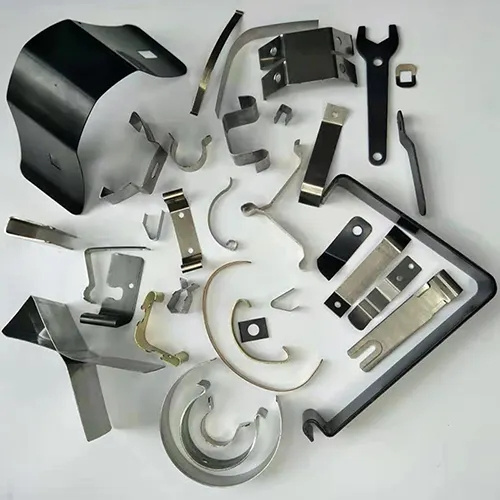

The Design Process for Custom Fourslide Clamps: From Concept to Prototype

We approach the design of custom Fourslide Clamps as a collaborative journey, starting with a deep dive into a client’s unique manufacturing needs. The process begins with a detailed consultation to understand the specific challenge—whether it’s clamping an irregularly shaped part, handling a fragile material, or fitting into a space-constrained die. Our engineering team then translates these requirements into 3D CAD models, incorporating features like asymmetric jaws, extended arms, or specialized mounting points. We simulate how the clamp will perform under operating conditions, testing factors like clamping force distribution and material stress. Once the design is refined, we produce a prototype using rapid manufacturing techniques, allowing clients to test the custom Fourslide Clamps in their actual production environment. This iterative process—incorporating client feedback into design tweaks—ensures the final clamp not only meets specifications but also integrates seamlessly into existing workflows.

Material Customization for Fourslide Clamps: Matching Manufacturing Environments

Selecting the right material is critical for custom Fourslide Clamps, as it must withstand the unique conditions of each manufacturing environment. For high-temperature applications, such as stamping near furnaces, we use heat-resistant alloys like Inconel, which retains strength at temperatures over 1,000°F. In corrosive settings—like marine part manufacturing—we opt for 316 stainless steel or titanium to prevent rust and degradation. For clients working with food-grade equipment, we craft custom Fourslide Clamps from materials with FDA-approved coatings, ensuring they meet hygiene standards. We also consider weight constraints: in automated systems where every ounce matters, we use lightweight aluminum alloys without sacrificing durability. By tailoring the material to factors like temperature, chemical exposure, and load requirements, we ensure the custom clamps perform reliably in their specific manufacturing context.

Custom Fourslide Clamps for Odd-Shaped or Irregular Parts

Manufacturing odd-shaped or irregular parts often requires clamping solutions that standard Fourslide Clamps can’t provide, which is where custom designs shine. We’ve created clamps with contoured jaws that mirror the exact shape of a part—for example, curved jaws to secure cylindrical tubing during stamping, or notched jaws to grip parts with protruding features. For asymmetrical components, such as automotive exhaust brackets with uneven surfaces, we design custom Fourslide Clamps with offset jaws that apply pressure evenly across the part, preventing distortion. We also incorporate adjustable pivot points in some designs, allowing operators to angle the clamp to match the part’s geometry. These tailored solutions eliminate the need for makeshift fixes, reducing scrap rates and ensuring consistent quality when working with non-standard parts.

Adapting to Space Constraints: Compact Custom Fourslide Clamps

In manufacturing setups with limited space—such as tight die cavities or small automated cells—compact custom Fourslide Clamps provide the clamping power needed without sacrificing maneuverability. We’ve engineered ultra-slim clamps with flattened profiles that fit into gaps as narrow as 0.5 inches, ideal for stamping parts in multi-cavity dies. For vertical stamping presses where height is restricted, we design low-profile Fourslide Clamps with shortened bodies that maintain clamping force despite their compact size. Some custom clamps feature rotating jaws that fold or pivot, allowing them to fit into tight spaces during setup and then expand to grip the material. These space-saving designs ensure manufacturers don’t have to compromise on clamping performance, even in the most confined manufacturing environments.

Custom Fourslide Clamps with Integrated Features for Enhanced Functionality

To address complex manufacturing needs, we design custom Fourslide Clamps with integrated features that go beyond basic clamping, enhancing overall process efficiency. For example, we’ve added sensor mounts to clamps used in automated lines, allowing real-time monitoring of part position or clamping force. In high-precision stamping, custom clamps include built-in alignment pins that mate with holes in the material, ensuring perfect positioning without manual adjustment. We’ve also integrated quick-release mechanisms into clamps for high-changeover environments, reducing setup time from minutes to seconds. For clients needing traceability, some custom Fourslide Clamps include RFID tags that log usage data, aiding in maintenance scheduling and quality control. These integrated features transform clamps from simple tools into multi-functional components that streamline manufacturing workflows.

Cost-Benefit of Custom Fourslide Clamps in Specialized Manufacturing

While custom Fourslide Clamps require an initial investment in design and tooling, their long-term cost benefits in specialized manufacturing are substantial. By eliminating scrap from poorly fitting standard clamps, custom designs reduce material waste—we’ve seen clients cut scrap rates by up to 40% in niche applications. Their tailored fit also reduces rework, as parts are held correctly during stamping, lowering labor costs. In high-volume production, the efficiency gains from faster changeovers and reduced downtime often offset the initial design costs within months. For manufacturers with unique processes, custom Fourslide Clamps can also enable capabilities that weren’t possible with standard equipment, opening up new production opportunities. Ultimately, the cost-benefit lies in their ability to solve specific challenges that would otherwise hinder quality, efficiency, or scalability in specialized manufacturing.