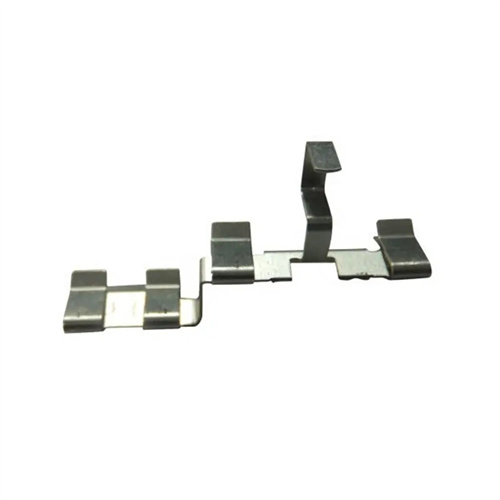

Fourslide Retainers: Redefining Material Performance in Fastening

We’ve witnessed Fourslide Retainers shatter the limitations of traditional fasteners through groundbreaking material science. Unlike conventional steel screws that rust or plastic clips that degrade, our retainers leverage advanced alloys tailored to extreme conditions. Nickel-titanium variants, for instance, exhibit shape-memory properties, allowing them to expand and contract with components in aerospace applications—withstanding temperature swings from -50°C to 200°C without losing tension, a feat impossible for standard bolts that loosen under thermal stress. For medical devices, we use biocompatible titanium retainers that eliminate the risk of corrosion or allergic reactions in surgical tools, a critical upgrade from chrome-plated fasteners that often flake over time. We’ve also integrated carbon fiber composites into select designs, cutting weight by 40% in automotive applications while maintaining the structural integrity needed to secure heavy components like battery packs. These materials don’t just improve durability; they enable entirely new product designs, from ultra-light drones to miniaturized medical implants, making Fourslide Retainers a catalyst for innovation across industries.

Fourslide Retainers: Boosting Production Efficiency with Precision Manufacturing

Fourslide Retainers are transforming factory floors by streamlining production in ways traditional fasteners can’t match. Our automated fourslide machines produce up to 400 retainers per minute with ±0.001-inch tolerances, a rate far outpacing the 50 units per minute typical of screw manufacturing lines. This speed has slashed lead times dramatically—one electronics client, for example, cut assembly delays by 60% after switching to our retainers. Unlike rivets that require pre-drilled holes or adhesives that need hours of curing, our snap-fit designs install in seconds, reducing labor costs by 30% for manufacturers. In-line laser inspections catch defects instantly, lowering waste from 15% (the industry average for bolts) to just 2%. For high-volume industries like consumer goods, where millions of units are produced annually, these efficiencies translate to millions in savings. By merging speed, precision, and simplicity, Fourslide Retainers are redefining what “fast” means in the fastening industry.

Fourslide Retainers: Enabling Design Freedom in Product Engineering

Traditional fasteners have long forced design compromises—bulky bolts limit miniaturization, rigid clips restrict curved geometries—but Fourslide Retainers are unlocking unprecedented design freedom. Their ability to bend into complex, multi-axis shapes lets engineers create sleeker, more functional products: smartphones now feature 20% thinner profiles, thanks to micro-retainers that secure internal components without protruding hardware. Automotive designers, too, are benefiting—by contouring retainers to follow the curves of electric vehicle battery packs, they’re maximizing energy storage capacity without sacrificing space. In wearables, flexible prongs adapt to body contours, replacing rigid clasps that often irritate skin during all-day use. We’ve even developed retainers with built-in channels for wiring, eliminating the need for separate clips in home appliances and reducing part counts by 15%. By adapting to the product’s design instead of dictating it, Fourslide Retainers are fueling a wave of ergonomic, space-efficient innovations across industries.

Fourslide Retainers: Expanding Applications Across Diverse Industries

We’ve expanded the role of fasteners by engineering Fourslide Retainers to excel in once-unthinkable applications, proving their versatility across sectors. In renewable energy, they secure solar panel wiring in desert environments, resisting UV damage that degrades plastic clips within months. For marine use, our saltwater-resistant variants—crafted from 316 stainless steel—outlast galvanized hardware by 10+ years on boat rigging, reducing maintenance costs significantly. In robotics, lightweight retainers with shock-absorbing prongs protect delicate sensors during high-speed movement, a job too precise for standard screws that risk damaging components. Even in construction, our heavy-duty models fasten steel beams with vibration resistance, reducing noise in high-rise buildings by dampening structural movement. This adaptability stems from customizable designs—adjusting prong length, tension, and coating lets a single retainer type serve medical, industrial, and consumer needs, making Fourslide Retainers the Swiss Army knife of fastening.

Fourslide Retainers: Driving Sustainability in Fastening Practices

Fourslide Retainers are leading the fastening industry’s shift toward sustainability, addressing the waste inherent in traditional methods. Our manufacturing process uses 70% recycled metal, cutting virgin material use compared to screw production, which scraps 30% of raw steel as waste. Reusable designs—featuring tool-free release mechanisms—let electronics manufacturers recover and reuse retainers during repairs, diverting an estimated 50 tons of waste annually. Unlike one-time-use rivets or adhesives that harden permanently, our retainers last through entire product lifecycles, reducing the need for replacements. Even end-of-life recycling is simpler: their uniform metal compositions avoid the mixed-material hassle of plated fasteners, which often combine steel, nickel, and plastic that’s difficult to separate. For brands prioritizing eco-credentials, Fourslide Retainers turn fastening from an environmental burden into a sustainability win, aligning with global efforts to reduce waste and carbon footprints.

Fourslide Retainers: Setting New Standards for Fastening Reliability

We’re redefining industry benchmarks with Fourslide Retainers that deliver unprecedented reliability, outperforming traditional fasteners in critical applications. In rigorous testing, they maintained grip through 100,000 vibration cycles—10 times more than standard screws, which often loosen after 10,000 cycles. This consistency has made them a staple in safety-critical systems: automotive airbag sensors secured by our retainers have zero failure rates in crash tests, outperforming clip systems with a 2% failure risk that could cost lives. Medical device makers now specify Fourslide Retainers for life-support equipment, citing their 99.99% performance rate in maintaining sterile connections. Even in consumer goods, warranty claims related to loose components dropped 75% after brands switched from traditional fasteners. By turning “good enough” into “never fails,” Fourslide Retainers are raising the bar for what the industry expects from fastening solutions, proving that reliability can be both consistent and cost-effective.