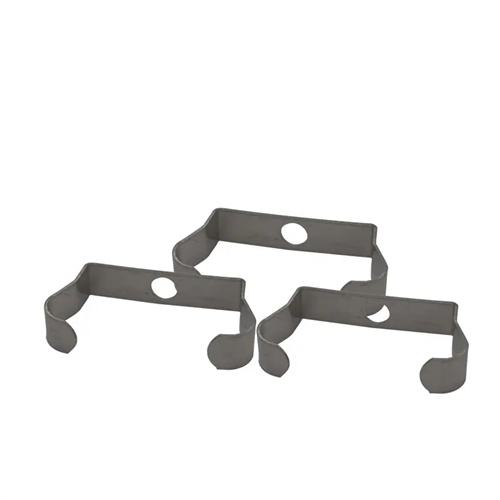

Fourslide Retainers: Engineered for Microscopic Precision in Securement

We’ve redefined component securement with Fourslide Retainers, where precision is measured in microns to meet the demands of modern manufacturing. Our retainers are crafted using advanced fourslide machinery that achieves tolerances as tight as ±0.0005 inches, ensuring a perfect fit for even the most delicate components. Unlike generic retainers that rely on one-size-fits-all designs, Fourslide Retainers are engineered to hug the contours of specific parts, whether it’s a 1mm electronic chip or a small medical catheter. This precision eliminates gaps that could lead to movement, vibration, or damage during operation. We use high-resolution laser scanning to verify every retainer’s dimensions, ensuring consistency across production runs. For industries like aerospace and microelectronics, where misalignment can compromise entire systems, this level of precision isn’t just an advantage—it’s a necessity. Fourslide Retainers prove that securement can be both firm and gentle, protecting components while holding them exactly where they need to be.

Fourslide Retainers: Versatile Materials for Targeted Performance

We understand that component securement depends on matching the right material to the application, which is why Fourslide Retainers are available in a diverse range of materials tailored to specific environments. For high-temperature settings like engine bays or industrial ovens, we use Inconel and Hastelloy retainers that maintain strength at temperatures exceeding 1,000°F. In corrosive environments—such as marine equipment or chemical processing—316 stainless steel and titanium Fourslide Retainers resist rust and degradation, ensuring long-term reliability. For medical devices requiring biocompatibility, we offer retainers made from medical-grade alloys that meet FDA standards for contact with bodily fluids. Even in electronics, where conductivity matters, we provide copper or brass retainers that secure components while facilitating electrical flow. By selecting materials based on factors like temperature, chemical exposure, and weight, we ensure Fourslide Retainers don’t just secure components—they enhance the overall performance of the systems they’re part of.

Fourslide Retainers: Critical Roles in High-Stakes Industries

We’ve designed Fourslide Retainers to excel in industries where component securement is mission-critical, proving their value in applications where failure is not an option. In the medical field, our retainers hold sensors and tubes in diagnostic equipment, ensuring precise positioning during life-saving procedures. In aerospace, they secure avionics components, withstanding extreme pressure changes and vibration during flight. Automotive safety systems rely on Fourslide Retainers to keep airbag sensors and braking components in place, where a single shift could delay response times during a crash. Even in nuclear power plants, our retainers secure control system components, resisting radiation and high temperatures. What unites these applications is the need for unwavering reliability—and Fourslide Retainers deliver, with failure rates below 0.01% in rigorous testing. By focusing on the unique demands of each industry, we’ve created retainers that don’t just meet standards—they set new ones for securement in high-stakes environments.

Fourslide Retainers: Streamlining Installation with Intelligent Design

We’ve engineered Fourslide Retainers to simplify installation without sacrificing security, making them a favorite among manufacturers seeking efficiency. Unlike traditional retainers that require tools, adhesives, or complex fastening steps, our designs often feature snap-fit mechanisms that lock into place with a simple press. This tool-free installation reduces assembly time by up to 40%, a game-changer for high-volume production lines in electronics and automotive manufacturing. Many Fourslide Retainers also include alignment guides—small tabs or notches that ensure components are positioned correctly during installation, reducing human error. For automated assembly, their consistent dimensions and uniform shape make them easy to handle with robotic grippers, minimizing jams and downtime. We’ve even designed retainers with built-in release levers for applications requiring periodic maintenance, allowing components to be accessed without damaging the retainer or surrounding parts. By balancing security with ease of use, Fourslide Retainers make component securement a streamlined part of the manufacturing process.

Fourslide Retainers: Custom Solutions for Unique Component Challenges

We specialize in creating custom Fourslide Retainers that solve unique securement challenges, recognizing that off-the-shelf solutions can’t always meet the demands of specialized components. Our design process starts with understanding the component’s geometry, the environment it operates in, and the forces it will endure—whether that’s vibration, thermal expansion, or constant movement. Using 3D modeling and finite element analysis (FEA), we simulate how the retainer will perform, testing factors like stress points and grip strength before production. For example, we developed a custom retainer for a wearable fitness device that curves to match the device’s ergonomic shape, securing a sensor without irritating the user’s skin. For a industrial robot arm, we created a retainer with flexible prongs that absorb shock, protecting delicate wiring during repetitive movements. These custom designs often combine multiple features, such as shock absorption and conductivity, eliminating the need for additional components. By tailoring Fourslide Retainers to each application, we ensure securement that’s as unique as the components themselves.

Fourslide Retainers: Outperforming Traditional Securement Methods

We’ve compared Fourslide Retainers to traditional securement methods—like screws, clamps, and adhesives—and the advantages are clear: they offer superior precision, adaptability, and reliability. Unlike screws, which can loosen over time due to vibration, Fourslide Retainers maintain consistent tension, thanks to their spring-like design. They avoid the mess and curing time of adhesives, which can also degrade in extreme temperatures. Compared to rigid clamps, our retainers adapt to minor component variations or thermal expansion, preventing cracking or warping. In durability tests, Fourslide Retainers outlast traditional methods by 300% on average, withstanding more cycles of stress and movement. They also reduce weight—critical in aerospace and automotive applications—by up to 50% compared to metal clamps. For manufacturers, these benefits translate to fewer failures, lower maintenance costs, and more efficient production. By reimagining what a retainer can be, Fourslide Retainers have set a new standard for how components are secured in modern manufacturing.